If you’re familiar with lithium batteries, you know that they are made up of cells. This concept isn’t so foreign if you consider that a sealed lead acid (SLA) battery is also made of cells. Both battery chemistries require cell balancing, but what is cell balancing? How does cell balancing happen? How does this affect performance?

Before we go into LiFePO4 cell balancing, here is a quick refresher on building the battery. Different applications have different voltage and amp-hour requirements, and therefore a battery may have as little as one cell, or it may have many cells. For example, it takes 4 x LiFePO4 cells (each with 3.2-volts) to make up a 12.8-volt battery. The lead acid 12-volt equivalent is made up of 6 x 2-volt lead acid cells.

Before the battery is built, it is important to ensure all the LiFePO4 cells are matched – in capacity rating, in voltage, and in internal resistance – and they must also be balanced after manufacturing.

WHAT IS CELL BALANCING?

The term balancing comes from the matching of the cells by capacity and voltage, and controlling their voltages through cycling the battery to maintain the balance, or close to equal voltages at all State of Charge (SOC) levels. It is important to note that cell balancing happens before and after a battery is built and must happen throughout the battery’s life for the battery to maintain optimal performance. This is a similar concept to how we maintain balance between individual batteries when we place them into series.

BALANCING LIFEPO4 CELLS

LiFePO4 battery packs ( or any lithium battery packs) have a circuit board with either a balance circuit, protective circuit module (PCM), or battery management circuit (BMS) board that monitor the battery and its cells. In a battery with a balancing circuit, the circuit simply balances the voltages of the individual cells in the battery with hardware when the battery approaches 100% SOC – the industry standard for lithium iron phosphate is to balance above a cell voltage of 3.6-volts. In a PCM or BMS, balance is also typically maintained by hardware, however there are additional protections or management capabilities within the circuitry that protects the battery that go beyond what a balance circuit does, such as limiting the battery charge/discharge current.

SLA battery packs are not monitored in the same way as lithium, so they aren’t balanced in the same way. A SLA battery is balanced by charging the battery with a slightly higher voltage than normal. Since the battery doesn’t have any internal monitoring, they will need to be monitored by an external device (called a hydrometer) or person as to prevent thermal runaway. This is not done automatically but is usually performed in a routine maintenance schedule.

ACTIVE VS PASSIVE CELL BALANCING

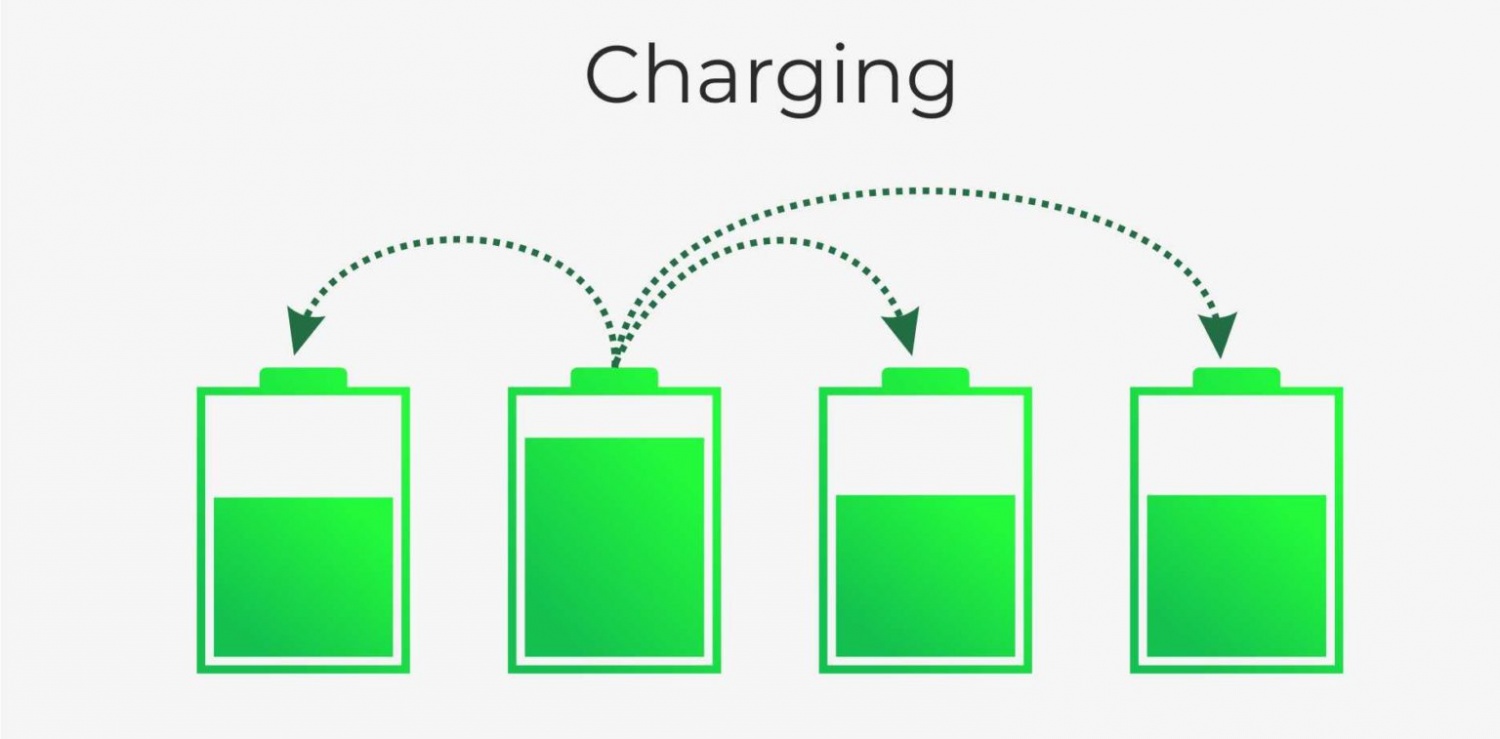

Passive cell balancing is where the current entering the battery is bled off through resistors. In this scenario, the current enters the battery and fills the cells. If one cell is “full”, the resistors take that energy and burns it off (turning it to heat) so that way the current flowing into the full cell is lessened until all cells are balanced.

Active cell balancing directs the current towards the least full cells first and discharges the “full” cells to charge the “low” cells. In this case, the current enters the battery and instead of filling all cells at the same rate, concentrates on filling the emptier cells until they reach the level of the other cells. Once all cells are equal, the current is directed equally into all cells until fully charged (and fully balanced).

Active and passive cell balancing each perform the same function; the only difference is active balancing is faster and more efficient.

WHY DOES BALANCING LIFEPO4 CELLS MATTER?

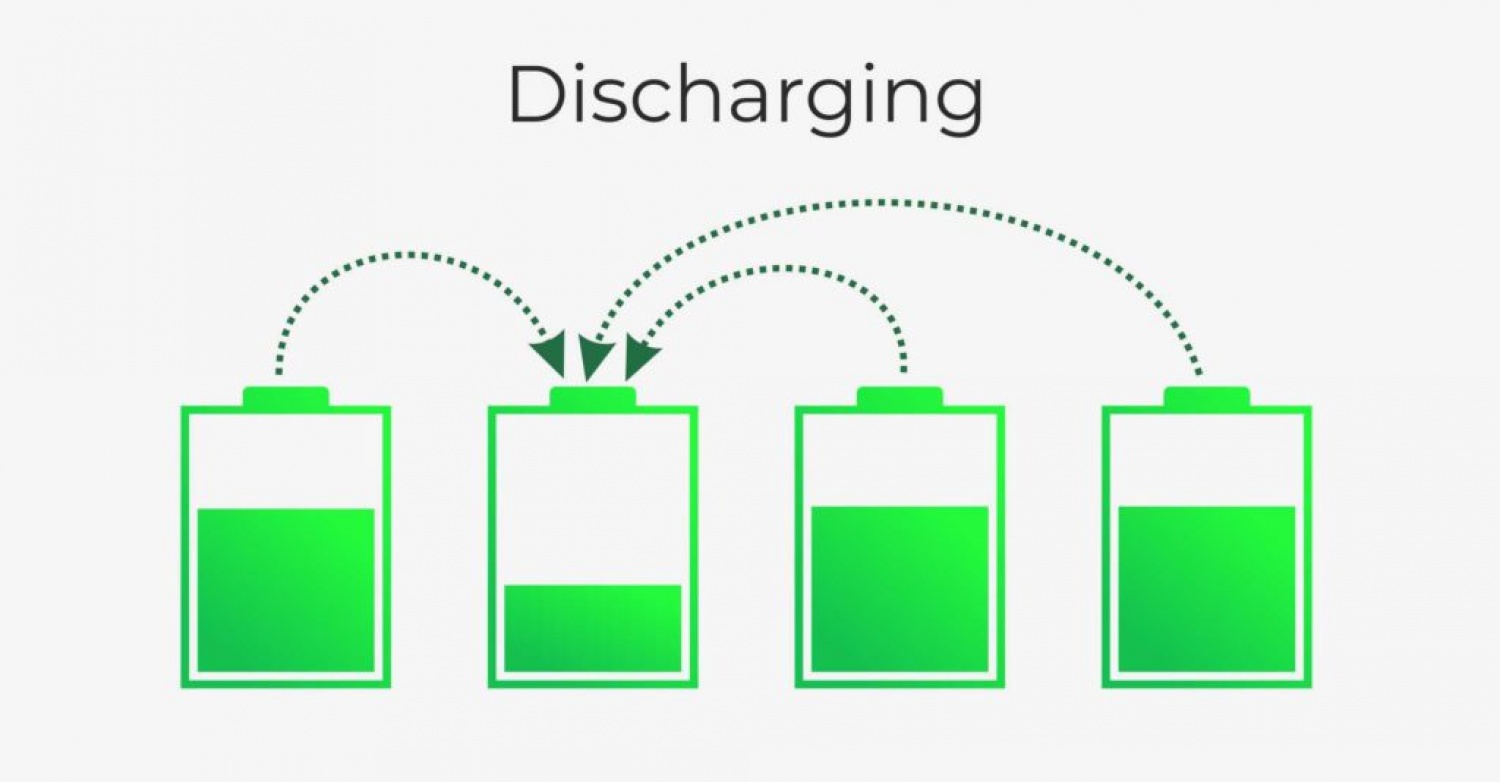

In LiFePO4 batteries, as soon as the cell with the lowest voltage hits the discharge voltage cut off designated by the BMS or PCM, it will shut down the entire battery. If the cells were unbalanced during discharge, this may mean that some cells have unused energy and that the battery isn’t truly “empty”. Likewise, if the cells aren’t balanced when charging, charging will be interrupted as soon as the cell with the highest voltage reaches the cut-off voltage and not all the LiFePO4 cells will be fully charged, and the battery won’t be either.

What’s so bad about that? To start, an unbalanced battery will have a lower capacity and a higher cut-off voltage at the battery level. Additionally, continuously charging and discharging an imbalanced battery will exacerbate this over time. The relatively linear discharge profile of LiFePO4 cells makes it increasingly important that all cells are matched and balanced – the greater the difference between the cell voltages, the lower the obtainable capacity.

The theory is that balanced cells all discharge at the same rate, and therefore cut-off at the same voltage every time. This isn’t always true, so having a balancing circuit (or PCM/BMS) ensures that upon charging, the battery cells can be fully balanced to maintain the battery’s design capacity and to become fully charged. Proper maintenance is key to getting the full life span out of your lithium battery, and cell balancing is a big piece of that.

If you have any further questions about cell balancing, lithium batteries, or anything else, please feel free to contact us.