Lithium-ion batteries are an alternative to metal lithium batteries that appeared in the past few years. The important components of the battery are the positive and negative electrodes, electrolyte, separator, and casing. The currently recognized basic principle of lithium-ion batteries is the so-called rocking chair theory. The charging and discharging of lithium-ion batteries does not realize the transfer of electrons in a traditional way, but the energy change occurs through the entry and exit of lithium ions in the crystals of the layered substance.

The working principle of lithium ion battery

The charging and discharging process of lithium-ion batteries is the process of Li+ intercalation and deintercalation in the positive and negative materials accompanied by the absorption and release of energy. Charge the lithium-ion battery: Li+ is deintercalated from the positive electrode material, reaches the negative electrode through the electrolyte, absorbs electrons, and is embedded in the negative electrode material to form a higher energy intercalation compound.

Lithium-ion battery is a kind of rechargeable battery, which mainly depends on the movement of lithium ions between the positive and negative electrodes to work. During the charging and discharging process, Li+ intercalates and deintercalates back and forth between the two electrodes: when recharging the battery, Li+ deintercalates from the positive electrode and inserts into the negative electrode through the electrolyte, and the negative electrode is in a lithium-rich state; the opposite is true during discharge. Generally, batteries that use materials containing lithium as electrodes are representative of modern high-performance batteries.

The charging and discharging process of lithium ion batteries is the process of intercalation and deintercalation of lithium ions. In the process of intercalation and deintercalation of lithium ions, it is accompanied by the intercalation and deintercalation of electrons equivalent to that of lithium ions (the positive electrode is usually represented by intercalation or deintercalation, and the negative electrode is denoted by insertion or deintercalation). During the charging and discharging process, lithium ions are intercalated/deintercalated and intercalated/deintercalated back and forth between the positive and negative electrodes, which is vividly called the rocking chair battery.

When the battery is charged, lithium ions are generated on the positive electrode of the lithium ion battery, and the generated lithium ions move to the negative electrode through the electrolyte. The carbon as the negative electrode has a layered structure. It has many micropores. The lithium ions reaching the negative electrode are embedded in the micropores of the carbon layer. The more lithium ions are inserted, the higher the charging capacity. Similarly, when the battery is discharged, the lithium ions embedded in the carbon layer of the negative electrode are released and move back to the positive electrode. The more lithium ions returned to the positive electrode, the higher the discharge capacity.

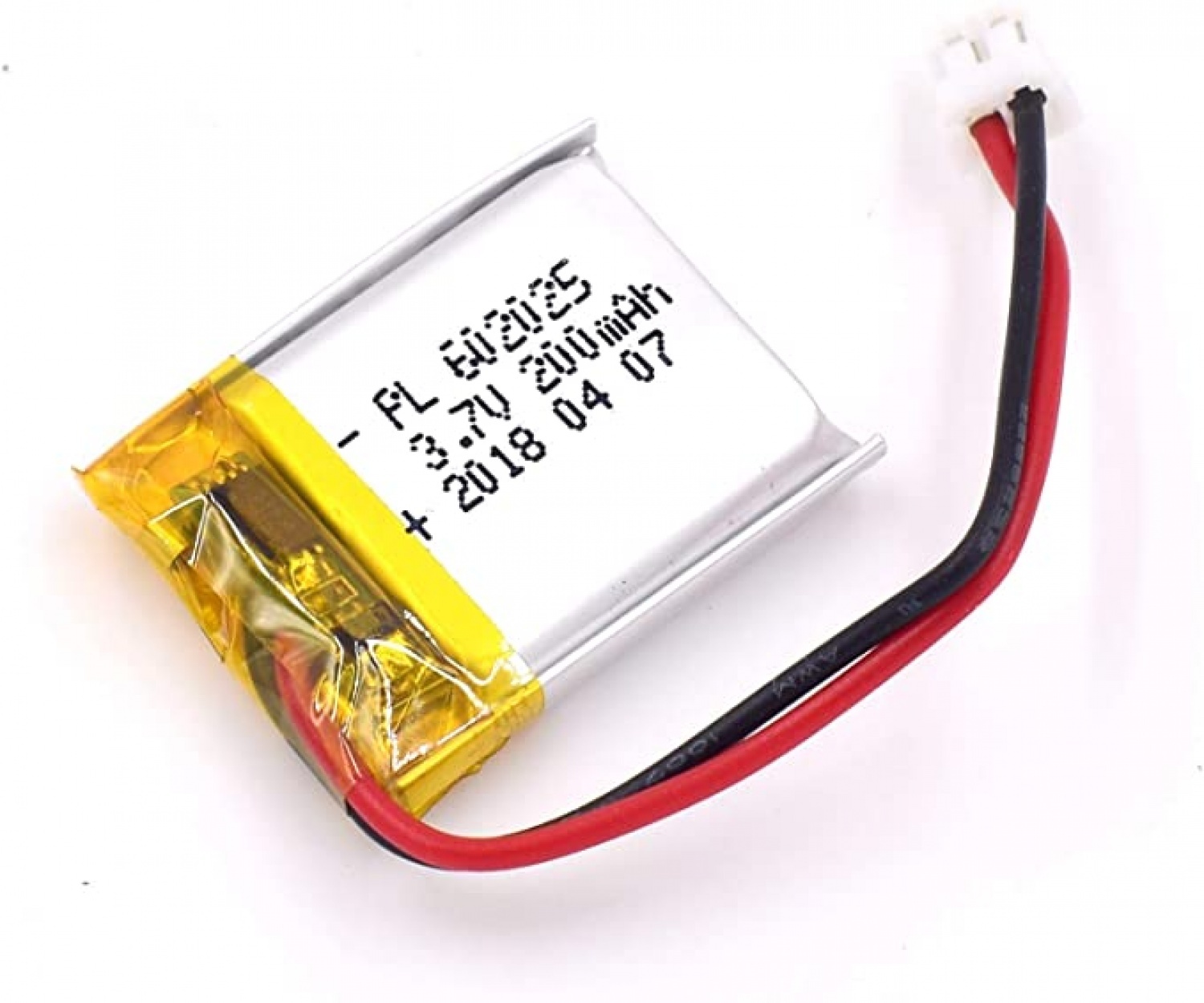

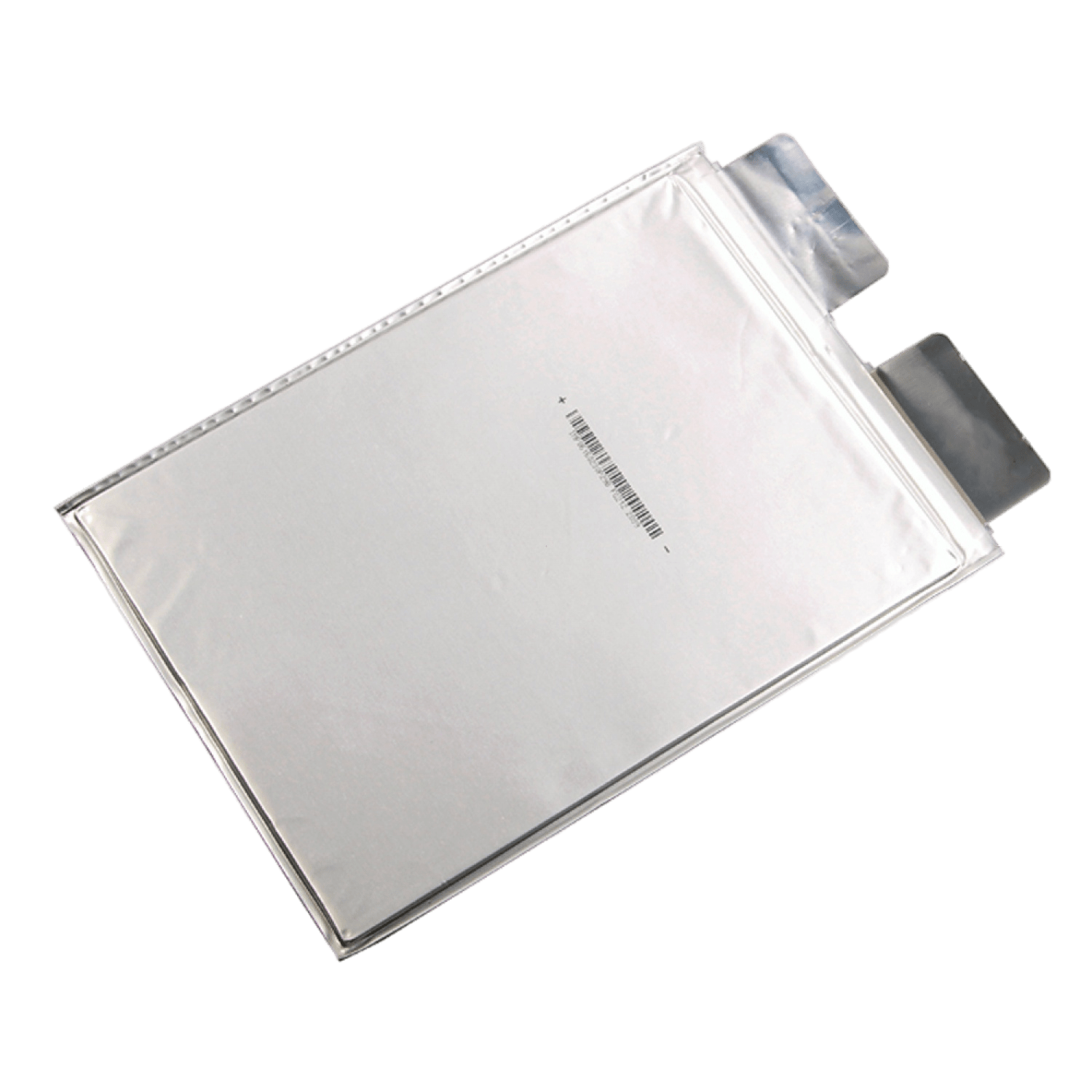

The structure of lithium-ion batteries

Lithium-ion batteries are an alternative to metal lithium batteries that appeared in the past few years. The important components of the battery are the positive and negative electrodes, electrolyte, separator, and casing.

Positive electrode-A carbon electrode that can absorb lithium ions is used. When discharging, lithium becomes lithium ions, leaving the anode of the battery and reaching the cathode of the lithium ion battery.

For the negative electrode-material, select a lithium compound that can be inserted as close as possible to the lithium potential. For example, various carbon materials include natural graphite, synthetic graphite, carbon fiber, mesosphere carbon, etc. and metal oxides.

Electrolyte-a mixed solvent system that uses LiPF6 ethylene carbonate, propylene carbonate and low-viscosity diethyl carbonate and other alkyl carbonates.

Diaphragm-the use of polyolefin microporous membranes such as PE, PP or their composite membranes, especially the PP/PE/PP three-layer membrane not only has a lower melting point, but also has a higher puncture resistance, which plays a role in heat insurance.

Principles of Lithium Ion Battery Charging and Discharging

The working principle of a lithium-ion battery refers to its charging and discharging principle. When the battery is charged, lithium ions are generated on the positive electrode of the battery, and the generated lithium ions move to the negative electrode through the electrolyte. The carbon as the negative electrode has a layered structure. It has many micropores. The lithium ions that reach the negative electrode are embedded in the micropores of the carbon layer. The more lithium ions are inserted, the higher the charging capacity.

It is not difficult to see that during the charging and discharging process of lithium-ion batteries, lithium ions are in a state of movement from positive electrode to negative electrode to positive electrode. If we compare the lithium ion battery to a rocking chair, the two ends of the rocking chair are the two poles of the battery, and the lithium ion is like an excellent athlete running back and forth on both ends of the rocking chair. Therefore, the experts gave the lithium-ion battery a lovely name, rocking chair battery.

Li-ion battery charge and discharge requirements

- Charging of Li-ion battery

The maximum end-of-charge voltage of a single-cell lithium-ion battery is 4.2V, and it cannot be overcharged, otherwise the battery will be scrapped due to the loss of too much lithium ions in the positive electrode. When charging lithium-ion batteries, a dedicated constant current and constant voltage charger should be used. First, charge with constant current until the voltage at both ends of the lithium-ion battery is 4.2V, then switch to constant voltage charging mode; when the constant voltage charging current drops to 100mA When, charging should be stopped.

- Discharge of Lithium Ion Battery

Due to the internal structure of lithium-ion batteries, all lithium ions cannot move to the positive electrode during discharge, and a part of lithium ions must be retained in the negative electrode to ensure that lithium ions can be inserted into the channel smoothly during the next charge. Otherwise, the battery life will be shortened. In order to ensure that some lithium ions remain in the graphite layer after discharge, it is necessary to strictly limit the minimum discharge termination voltage, which means that the lithium ion battery cannot be over-discharged.